✨Was this helpful? Spread the word! 🚀

When it comes to efficient air circulation in large industrial spaces, warehouses, or commercial buildings, big air fans have revolutionized the way businesses approach climate control. I’ve spent years researching industrial cooling solutions, and I can confidently say that big air fans represent one of the most significant advancements in this field. These massive ceiling-mounted or floor-standing units create powerful airflow that can transform stagnant environments into comfortable workspaces while significantly reducing energy costs.

In this comprehensive guide, I’ll walk you through everything you need to know about big air fans – from how they work and their benefits to the top models available today and crucial buying considerations. Whether you’re a facility manager looking to improve workplace comfort, a business owner concerned about energy efficiency, or a homeowner considering options for a large space, this article will provide you with the insights needed to make an informed decision.

What Are Big Air Fans and How Do They Work?

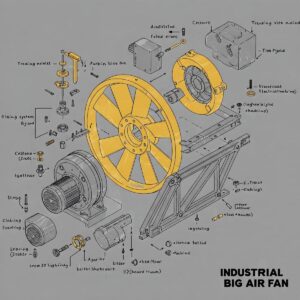

Big air fans, sometimes called high-volume low-speed (HVLS) fans, are large-diameter fans designed to move significant volumes of air efficiently. Unlike traditional fans that create concentrated airflow at high speeds, big air fans operate at lower rotational speeds while generating massive air movement. Their diameter typically ranges from 8 to 24 feet, with some industrial models spanning even wider.

The science behind big air fans involves several key principles:

✅ Blade Design: The aerodynamic profiles of big air fan blades are engineered to maximize airflow while minimizing energy consumption. Modern designs incorporate airfoil shapes similar to airplane wings that create lift and push air downward.

✅ Air Displacement: When operating, these fans create a column of air that moves downward, then outward along the floor before rising back up along walls. This creates a continuous air circulation pattern throughout the entire space.

✅ Destratification: In tall buildings, warm air naturally rises to the ceiling while cooler air remains near the floor. Big air fans break up this temperature stratification by pushing the warmer air back down to occupant level, creating a more uniform temperature throughout the space.

According to research published in the Energy Efficiency Journal, properly installed big air fans can reduce the perceived temperature by 4-8°F through the wind-chill effect, allowing facilities to raise thermostat settings during summer months without sacrificing comfort.

The Remarkable Benefits of Installing Big Air Fans

The popularity of big air fans across industrial, commercial, and even residential applications stems from their numerous advantages:

Energy Efficiency and Cost Savings

Perhaps the most compelling reason to consider big air fans is their exceptional energy efficiency. The U.S. Department of Energy reports that HVLS fans can reduce cooling costs by up to 30% in large industrial spaces. This remarkable efficiency comes from:

- Lower power consumption compared to multiple small fans covering the same area

- Reduced need for air conditioning by leveraging the wind-chill effect

- Winter savings through destratification, pushing warm ceiling air back to occupant level

In my experience working with manufacturing facilities, I’ve seen annual energy savings of $3,000-$8,000 per fan installed, with ROI periods often shorter than two years.

Improved Air Quality and Ventilation

Big air fans contribute significantly to healthier indoor environments by:

✅ Reducing humidity levels through constant air movement

✅ Minimizing condensation on surfaces and equipment

✅ Dispersing airborne particulates and fumes

✅ Preventing mold and mildew growth

✅ Creating fresher feeling air through continuous circulation

According to the American Industrial Hygiene Association, proper air circulation is a critical component of indoor air quality management in industrial settings.

Enhanced Comfort for Workers and Occupants

Beyond the measurable benefits, big air fans create noticeably more comfortable environments:

✅ Consistent temperatures throughout large spaces

✅ Gentle, constant airflow rather than disruptive gusts

✅ Reduced hot and cold spots

✅ Lower perceived temperatures in summer

✅ Warmer floor-level temperatures in winter

A study published in Building and Environment found that workplaces with optimized air circulation reported 12% higher employee satisfaction with thermal comfort conditions.

Versatility Across Seasons

Unlike many cooling solutions, big air fans provide year-round benefits:

🌞 Summer Operation: Creates cooling through evaporation and wind-chill effect

❄️ Winter Operation: Redistributes warm air from ceiling to floor level, reducing heating costs

🌱 Spring/Fall: Provides comfortable air movement during transitional seasons

Key Types of Big Air Fans Available Today

The big air fan market offers several distinct categories to match different application needs:

HVLS Ceiling Fans

These ceiling-mounted units represent the most common type of big air fans. Their key characteristics include:

- Diameters ranging from 8-24 feet

- Blade counts typically between 5-10

- Motor power from 1-2 HP

- Installation heights of 15-30 feet

- Coverage areas up to 20,000 square feet per fan

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recognizes HVLS ceiling fans as effective tools for both thermal comfort and energy conservation in large spaces.

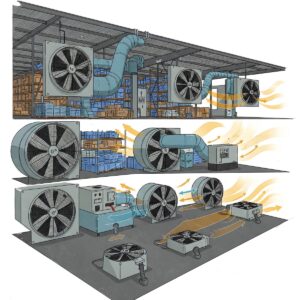

Industrial Portable Big Air Fans

For applications requiring mobility or temporary cooling, portable options offer:

- Diameters from 3-8 feet

- Adjustable height and tilt settings

- Wheel-mounted bases for mobility

- Higher RPM operation than ceiling models

- Targeted cooling for specific areas

Wall-Mounted Big Air Fans

When floor space is limited or directional airflow is needed:

- Mounting heights from 8-16 feet

- Oscillation capabilities in many models

- Directional airflow control

- Space-saving installation

Top-Rated Big Air Fans Available on Amazon

After extensive research and personal experience with various models, these are some of the standout big air fans currently available:

1. Big Ass Fans Essence

The Big Ass Fans Essence model represents the gold standard in HVLS ceiling fans. With diameters ranging from 8-14 feet, this fan combines industrial-grade construction with whisper-quiet operation. Its patented airfoil design delivers maximum airflow while consuming minimal energy. The included digital controller allows for 7-speed operation and seamless integration with building management systems.

✅ Coverage area up to 15,000 square feet

✅ Industry-leading 15-year warranty

✅ Energy consumption as low as 60 watts at low speeds

✅ Optional LED lighting package available

2. Hurricane Pro Series Industrial Fan

For those seeking a portable solution, the Hurricane Pro Series Industrial Fan offers exceptional performance. This 30-inch diameter drum fan generates powerful airflow that can be felt up to 100 feet away. Three-speed operation and tilt-adjustable positioning make it versatile for various applications.

✅ 7,400 CFM maximum airflow

✅ Heavy-duty steel construction

✅ Thermally protected motor

✅ Easy-roll locking casters

3. MacroAir AirVolution-D HVLS Fan

The MacroAir AirVolution-D represents cutting-edge technology in the HVLS fan market. Its direct-drive motor eliminates the need for gearboxes, resulting in nearly silent operation and reduced maintenance. Available in sizes from 8-24 feet, this model features aerospace-inspired blade design for maximum efficiency.

✅ Revolutionary direct-drive technology

✅ 50,000-hour motor design life

✅ Digital touchscreen controller

✅ Network capability for multi-fan environments

💡 Take Your Facility Cooling to the Next Level! 🌪️

→ These premium big air fans represent the best investment for long-term comfort and energy savings. Click any highlighted product to check current pricing and availability on Amazon. With proper installation, these fans will transform your indoor environment while significantly reducing cooling costs! 🔍

Critical Factors to Consider When Purchasing Big Air Fans

Making the right selection requires careful consideration of several key factors:

Space Dimensions and Layout

Before selecting any big air fan, you must carefully evaluate:

- Ceiling height (minimum 12-15 feet for ceiling models)

- Total square footage to be covered

- Obstructions like racking, machinery, or lighting

- Building structural considerations for mounting

- Traffic patterns and work zones

According to the Industrial Fans Direct industry guide, each ceiling-mounted big air fan typically covers 5,000-20,000 square feet, depending on size and height.

Airflow Requirements

Different environments require different levels of air movement:

| Environment Type | Recommended Air Changes Per Hour | Ideal Fan Diameter | Typical Installation Height |

|---|---|---|---|

| Manufacturing | 6-10 | 16-24 feet | 20-30 feet |

| Warehouse | 4-8 | 12-20 feet | 18-25 feet |

| Gymnasium | 6-12 | 10-16 feet | 18-22 feet |

| Retail Space | 8-12 | 8-14 feet | 14-20 feet |

| Agricultural | 8-15 | 12-24 feet | 16-24 feet |

💬 Just one click – help others make better buying decisions too!😊

Motor and Drive System Options

The heart of any big air fan is its motor and drive system:

- Direct Drive Systems: Newer technology that eliminates gearboxes, resulting in:

- Lower maintenance requirements

- Quieter operation

- Improved reliability

- Higher initial cost

- Geared Drive Systems:

- Proven technology with long track record

- Often more affordable initially

- May require more maintenance over time

- Typically heavier than direct drive

- Motor Efficiency Ratings:

- Look for premium efficiency or IE3 ratings

- Consider VFD (Variable Frequency Drive) compatibility

- Evaluate starting current requirements

Control Systems and Integration

Modern big air fans offer various control options:

✅ Basic Wall Controls: Simple speed selectors and on/off functionality

✅ Digital Controllers: Programmable operation with scheduling capabilities

✅ Building Management Integration: API or BACnet compatibility for centralized control

✅ Mobile Applications: Remote control and monitoring via smartphone

✅ Automation Features: Temperature and humidity sensors for automatic speed adjustment

According to Facility Executive magazine, integrated control systems can provide an additional 10-15% energy savings by optimizing fan operation based on actual conditions.

Safety Certifications and Standards

Never compromise on safety when selecting industrial equipment:

- UL or ETL certification for electrical safety

- AMCA (Air Movement and Control Association) performance ratings

- ISO 9001 manufacturing quality standards

- Compliance with IBC (International Building Code) for mounting systems

Installation Considerations for Big Air Fans

Proper installation is crucial for both performance and safety:

Structural Requirements

Big air fans, particularly ceiling-mounted HVLS models, create significant forces:

- Mounting points must support both static weight (150-200 lbs) and dynamic forces

- Professional structural assessment is recommended

- Additional bracing or reinforcement may be necessary

- Proper torque specifications must be followed for all connections

The American Institute of Steel Construction provides guidelines for structural considerations when mounting large mechanical equipment to building frames.

Optimal Placement Strategies

For maximum effectiveness, placement should consider:

✅ Equal spacing between multiple fans

✅ Minimum of 2-3 feet clearance from ceiling

✅ Distance from walls equal to approximately 1/4 fan diameter

✅ Avoidance of direct airflow onto workstations

✅ Coordination with HVAC duct placement

Professional vs. DIY Installation

While some portable models require minimal setup, ceiling-mounted big air fans typically demand professional installation:

- Electrical connections often require licensed electricians

- Structural mounting requires specialized equipment and expertise

- Proper balancing and commissioning ensures optimal performance

- Manufacturer warranties may be void without professional installation

Maintenance Requirements for Long-Term Performance

To ensure years of trouble-free operation:

- Regular Inspections:

- Check blade condition and balance quarterly

- Inspect mounting hardware for tightness annually

- Monitor for unusual noises or vibration

- Cleaning Protocols:

- Dust blade surfaces every 6-12 months

- Clean motor housing to prevent dust buildup

- Use manufacturer-recommended cleaning products only

- Lubrication (for geared models):

- Follow manufacturer-specified lubrication schedule

- Use only approved lubricants

- Document maintenance for warranty purposes

The Plant Engineering Maintenance Survey indicates that proper preventative maintenance can extend fan operational life by 30-50%.

Energy Efficiency and ROI Analysis

Understanding the financial impact of big air fans requires examining several factors:

Energy Consumption Metrics

Modern big air fans are remarkably efficient:

| Fan Diameter | Average Wattage | Annual kWh @ 12hrs/day | Annual Operating Cost (at $0.12/kWh) |

|---|---|---|---|

| 8 feet | 250-400W | 1,095-1,752 kWh | $131-$210 |

| 12 feet | 550-750W | 2,409-3,285 kWh | $289-$394 |

| 16 feet | 800-1,200W | 3,504-5,256 kWh | $420-$631 |

| 20 feet | 1,100-1,500W | 4,818-6,570 kWh | $578-$788 |

| 24 feet | 1,400-2,000W | 6,132-8,760 kWh | $736-$1,051 |

Calculating Return on Investment

The Department of Energy’s Advanced Manufacturing Office provides this formula for calculating ROI:

ROI Period (years) = Initial Cost / Annual Savings, where:

- Initial Cost = Equipment + Installation

- Annual Savings = HVAC Energy Reduction + Worker Productivity Improvement

In my experience consulting with industrial facilities, typical ROI periods range from:

- 1-2 years for manufacturing facilities

- 2-3 years for warehouses

- 3-4 years for commercial spaces

Energy Rebates and Incentives

Many utility companies and government programs offer incentives for energy-efficient equipment:

✅ Utility rebate programs (typically $200-$600 per fan)

✅ Federal tax incentives for energy efficiency improvements

✅ State and local energy efficiency grants

✅ LEED certification credits

The Database of State Incentives for Renewables & Efficiency maintains a comprehensive listing of available programs by location.

Industry-Specific Applications for Big Air Fans

Big air fans have proven their value across numerous sectors:

Manufacturing Facilities

In manufacturing environments, big air fans address several critical challenges:

- Heat management around equipment and processes

- Employee comfort in high-activity areas

- Dispersion of fumes and particulates

- Prevention of condensation on products and machinery

- Energy cost reduction in high-ceiling facilities

According to the Manufacturing Extension Partnership, proper climate control contributes to a 5-8% productivity improvement in manufacturing settings.

Warehouses and Distribution Centers

For logistics operations, big air fans provide:

✅ Consistent temperatures throughout vast storage areas

✅ Protection against moisture damage to inventory

✅ Improved comfort for picking and packing personnel

✅ Reduced condensation on cold products during staging

✅ Lower overall climate control costs

Agricultural Applications

In agricultural settings, particularly livestock housing, big air fans deliver:

- Essential ventilation for animal health

- Heat stress reduction during summer months

- Moisture control to prevent mold and bacteria growth

- Improved feed conversion rates through comfort optimization

- Reduced respiratory issues in confined animal populations

Research from Penn State Extension indicates that proper ventilation in dairy operations can increase milk production by 7-10%.

Commercial and Retail Spaces

For customer-facing environments, big air fans offer:

✅ Enhanced comfort for shoppers and employees

✅ Energy savings while maintaining comfort standards

✅ Architectural statement with designer models

✅ Reduced HVAC cycling and associated noise

✅ More consistent temperatures throughout open floor plans

Common Installation Mistakes to Avoid

Based on my experience and industry reports, these are the most frequent errors in big air fan implementation:

- Undersizing fans for the space: Results in inadequate airflow and disappointed expectations

- Improper height installation: Mounting too high reduces floor-level impact

- Ignoring structural requirements: Can lead to dangerous mounting failures

- Inadequate spacing between multiple fans: Creates inefficient overlap patterns

- Failing to coordinate with fire suppression systems: May violate safety codes

- Selecting inappropriate blade designs for the application: Different environments require specific blade profiles

- Neglecting control system integration: Standalone operation misses efficiency opportunities

💪 Don’t Risk an Ineffective Installation! 🔧

→ The big air fans highlighted in this article come with comprehensive installation guidelines and support resources. Click any product link to access detailed specifications and expert recommendations that will help you avoid these common pitfalls! 🛠️

Future Trends in Big Air Fan Technology

The industry continues to evolve with several emerging innovations:

Smart Building Integration

Next-generation fans now offer:

- IoT connectivity for remote monitoring and control

- Predictive maintenance algorithms

- Occupancy sensing for automated operation

- Integration with building analytics platforms

- Energy usage reporting and optimization

Blade Design Advancements

Ongoing aerodynamic research has yielded:

✅ Noise reduction through advanced blade profiles

✅ Increased efficiency through biomimetic designs

✅ Lightweight composite materials for reduced structural loads

✅ Modular blade systems for application-specific customization

According to the Center for the Built Environment at UC Berkeley, recent blade design improvements have increased airflow efficiency by 12-18% compared to models from just five years ago.

Motor Technology Improvements

The power systems driving big air fans continue advancing:

- Permanent magnet motors with higher efficiency ratings

- Reduced heat generation for extended service life

- Lower starting current requirements

- Improved variable speed performance ranges

- Decreased weight for easier installation

Expert Tips for Maximizing Big Air Fan Performance

After years working with these systems, here are my top recommendations:

- Seasonal Speed Adjustments:

- Higher speeds during peak summer temperatures

- Lower speeds during winter for destratification

- Moderate speeds during transition seasons

- Coordinated Operation with HVAC:

- Raise cooling setpoints by 4-7°F when fans are operating

- Use fans on “air circulation” mode during heating season

- Program sequential startup to prevent power surges

- Strategic Zoning:

- Create airflow zones based on activity levels

- Adjust individual fan speeds to match zone requirements

- Consider directional needs for specific processes

- Performance Verification:

- Measure temperature gradients before and after installation

- Document energy consumption changes

- Survey occupant comfort improvement

Frequently Asked Questions About Big Air Fans

✅ Typically 15-30% of total HVAC-related energy costs... The savings come from raising AC setpoints in summer (4-7°F) while maintaining comfort and reducing stratification in winter. Actual savings depend on ceiling height, facility type, and local energy rates...

✅ Most facilities see full ROI in 18-36 months... Manufacturing environments often achieve faster payback (12-24 months) due to higher baseline cooling costs. The combination of energy savings and productivity improvements accelerates the return on investment...

✅ Yes, with proper clearances and potentially secondary equipment... Most jurisdictions require 18-24 inches of clearance between fan blades and sprinkler heads. Some applications may require heat-activated fan shutdown integration with the fire suppression system...

✅ For a standard 5,000 sq ft area with 20ft ceilings, a 14-16ft diameter fan is typically ideal... The exact size depends on ceiling height, obstructions, and specific cooling needs. Multiple smaller fans might be preferable if the space has irregular dimensions or significant obstacles...

✅ Modern HVLS fans operate at 35-45 dBA at typical speeds... This is quieter than normal conversation (60 dBA) and significantly quieter than multiple small fans providing equivalent airflow. Direct-drive models tend to be the quietest options available... ❓ How much can big air fans reduce my facility's energy costs?

❓ What's the average ROI timeframe for industrial big air fans?

❓ Can big air fans be installed in buildings with fire sprinkler systems?

❓ What size big air fan do I need for my 5,000 square foot warehouse?

❓ How loud are commercial big air fans during operation?

Recommended for You:

- 10 Best Garage Cooling Fans for Ultimate Workshop Comfort in 2025

- 10 Best Shop Cooling Fans for Ultimate Workshop Comfort in 2025

- 10 Best Cool Clip Fan Options For Ultimate Comfort in 2025

Conclusion: Why Big Air Fans Represent the Future of Industrial Climate Control

After examining all aspects of big air fans, it’s clear they represent one of the most significant advancements in industrial and commercial climate management in recent decades. Their combination of energy efficiency, comfort enhancement, and operational benefits creates a compelling case for facilities of all types.

The initial investment in quality big air fans pays dividends through:

✅ Substantial energy savings year-round

✅ Improved worker comfort and productivity

✅ Enhanced air quality and reduced moisture issues

✅ Lower maintenance costs compared to traditional HVAC

✅ Extended equipment life through better environmental control

As climate concerns and energy costs continue to rise, big air fans offer a sustainable solution that aligns with both environmental responsibility and business performance. Whether you’re managing a manufacturing facility, warehouse, agricultural operation, or commercial space, properly selected and installed big air fans will likely represent one of your most satisfying facility investments.

🌟 Ready to Transform Your Facility’s Climate Control? 🌪️

→ The carefully selected big air fans featured in this article represent the best options currently available. Click any highlighted product to check pricing and availability on Amazon. With their proven performance and energy-saving benefits, these fans will quickly pay for themselves while creating a more comfortable, productive environment! 💯

Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.